Service Hotline:13510328459

Service Hotline:13510328459

205-206, 2nd Floor, Building 2, Xiazao Village Industrial Zone, Gaofeng Community, Dalang Street, Longhua District, Shenzhen City

205-206, 2nd Floor, Building 2, Xiazao Village Industrial Zone, Gaofeng Community, Dalang Street, Longhua District, Shenzhen City

Service Hotline:13510328459

Service Hotline:13510328459

205-206, 2nd Floor, Building 2, Xiazao Village Industrial Zone, Gaofeng Community, Dalang Street, Longhua District, Shenzhen City

205-206, 2nd Floor, Building 2, Xiazao Village Industrial Zone, Gaofeng Community, Dalang Street, Longhua District, Shenzhen City

Time:2025-11-12 Preview:

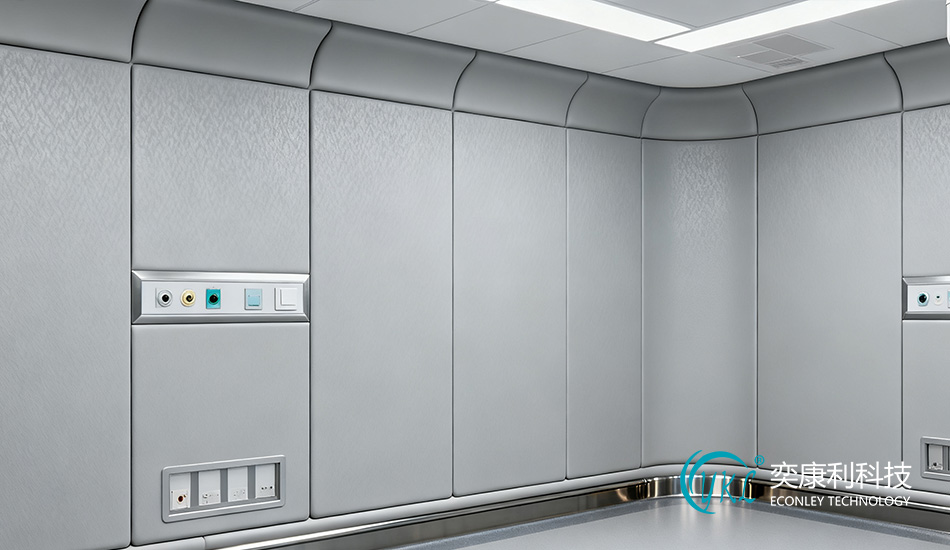

Operating rooms (ORs) require wall solutions that go beyond basic functionality—they must uphold sterility, withstand harsh conditions, and adapt to specialized medical equipment. The Operating Room Wall Panel is the unsung backbone of these spaces, merging medical-grade performance with practicality to support surgical teams and protect patients. Unlike generic wall materials, Operating Room Wall Panel is engineered exclusively for the unique demands of ORs: frequent disinfection, equipment impacts, and strict infection control protocols. As a leader in healthcare-grade materials, Econley offers a diverse range of Operating Room Wall Panel options, complemented by OR-specific accessories like sterile edge trims and equipment-mounting adapters. Our panels are designed to not just “cover walls” but to enhance OR safety, efficiency, and long-term cost-effectiveness.

What sets Operating Room Wall Panel apart from standard wall materials is its advanced material engineering, tailored to OR challenges:

The most widely used Operating Room Wall Panel option features a high-density PVC resin core infused with silver-ion antibacterial technology. Certified by SGS and ISO 13485, this material inhibits 99.99% of harmful pathogens (E. coli, MRSA, Pseudomonas aeruginosa) within 2 hours of contact. Its non-porous surface repels blood, bodily fluids, and cleaning chemicals, eliminating the risk of bacterial buildup in pores— a major flaw of painted drywall or tile. Unlike surface-only antibacterial treatments, the silver ions are embedded in the resin matrix, ensuring protection lasts for the panel’s 10+ year lifespan, even after 1,000+ cycles of high-pressure disinfection.

For hybrid ORs or rooms with radiation equipment (CT scanners, C-arms), Operating Room Wall Panel with lead-lining is non-negotiable. These panels feature a lead sheet (0.5mm–2mm thickness, customizable by radiation level) sandwiched between resin layers, blocking 99.9% of ionizing radiation to protect staff and patients. The lead core is fully encapsulated to prevent lead dust exposure, and the outer resin layer maintains the same antibacterial, easy-to-clean properties as standard panels. This dual-purpose design eliminates the need for separate radiation shielding, streamlining OR construction and reducing wall thickness.

ORs are high-traffic environments with constant movement of surgical tables, anesthesia carts, and equipment. Operating Room Wall Panel for high-impact zones (corridors, equipment bays) includes a fiberglass-reinforced core that meets EN 14411 Class 4 impact resistance—absorbing up to 50J of force without cracking or denting. The panels’ edges are rounded or beveled (10mm radius minimum) to minimize injury risk from collisions, while the surface resists scratches from equipment wheels. This durability reduces replacement costs: facilities report 70% fewer wall repairs after switching to reinforced Operating Room Wall Panel.

Beyond material quality, Operating Room Wall Panel delivers functional benefits that generic walls can’t match:

OR staff spend 25% of their time cleaning surfaces—and Operating Room Wall Panel cuts this time by 30%. Its non-porous surface requires only a wipe with medical-grade disinfectant (bleach, hydrogen peroxide) to achieve sterility, with no need for scrubbing grout lines or touch-ups. Panels also resist staining from iodine, betadine, or medication spills, maintaining a clean, professional appearance even after years of use.

Operating Room Wall Panel is pre-engineered to accommodate OR equipment:

Pre-cut holes (customizable size) for gas outlets, electrical sockets, and surgical lights—eliminating on-site cutting that risks contamination.

Reinforced mounting points (100kg weight capacity) for surgical booms, monitors, and anesthesia machines—no need for additional wall anchors.

Cable management channels (hidden within panels) for power and data lines—reducing clutter and infection risks from exposed wires.

While functionality is key, Operating Room Wall Panel also supports patient well-being. It’s available in 15+ calming colors (soft blues, sage greens, warm neutrals) proven to reduce patient anxiety. For pediatric ORs, panels can be customized with subtle, clinical-grade patterns (e.g., cloud motifs) that don’t compromise sterility. Matte finishes minimize glare from surgical lights, improving visibility for surgeons without straining eyes.

Econley’s Operating Room Wall Panel has transformed over 400 surgical facilities:

A 350-bed hospital in Munich installed lead-lined Operating Room Wall Panel in 8 hybrid ORs: “The panels simplified radiation compliance and cut cleaning time by 28%,” said their radiology director. “We haven’t had a single radiation leak incident in 2 years.”

A children’s hospital in Singapore used low-VOC, pastel-colored Operating Room Wall Panel in neonatal ORs: “Parents report less anxiety seeing softer colors, and the zero off-gassing keeps our fragile patients safe,” noted their NICU manager. “The panels also resist stains from baby formula and medical creams—critical for maintaining sterility.”

Selecting the best Operating Room Wall Panel requires aligning with your OR’s unique needs:

Assess OR Type: General surgery needs standard antibacterial panels; hybrid ORs require lead-lined options.

Evaluate Traffic & Impact Risk: Emergency ORs benefit from reinforced panels; low-traffic ICUs can use standard variants.

Check Compliance: Ensure panels meet local standards (FDA for U.S., CE for EU, ISO 13485 globally).

Test Samples: Request panel samples to verify disinfectant compatibility, impact resistance, and color in your OR’s lighting.

Plan for Future Needs: Choose modular panels if you anticipate equipment upgrades or OR expansions.

Econley’s Operating Room Wall Panel isn’t just a product—it’s a partnership. We provide:

Free on-site assessments to recommend the right panel type.

Custom cuts and modifications (no extra cost for equipment holes or lead thickness adjustments).

Post-installation training for staff on panel maintenance.

A 5-year warranty (extended to 10 years for bulk orders) covering defects, antibacterial performance, and impact resistance.

Operating Room Wall Panel is more than a wall—it’s an investment in patient safety, staff efficiency, and OR longevity. By choosing medical-grade panels over generic materials, facilities reduce infection risks, lower maintenance costs, and create environments that support world-class surgical care.

Contact Econley today to request Operating Room Wall Panel samples or a custom quote. Let’s build ORs that work as hard as your surgical team.