Service Hotline:13510328459

Service Hotline:13510328459

205-206, 2nd Floor, Building 2, Xiazao Village Industrial Zone, Gaofeng Community, Dalang Street, Longhua District, Shenzhen City

205-206, 2nd Floor, Building 2, Xiazao Village Industrial Zone, Gaofeng Community, Dalang Street, Longhua District, Shenzhen City

Service Hotline:13510328459

Service Hotline:13510328459

205-206, 2nd Floor, Building 2, Xiazao Village Industrial Zone, Gaofeng Community, Dalang Street, Longhua District, Shenzhen City

205-206, 2nd Floor, Building 2, Xiazao Village Industrial Zone, Gaofeng Community, Dalang Street, Longhua District, Shenzhen City

Time:2025-10-24 Preview:

In the world of scientific research and experimentation, the importance of a controlled environment cannot be overstated. Every detail, from the equipment used to the atmosphere maintained, plays a crucial role in ensuring accurate and reliable results. Among the many components of a laboratory, window screens often go unnoticed. However, they serve a vital function in maintaining the integrity of the laboratory environment. Let's explore the various types of laboratory window screens, their importance, and how they contribute to a safe and efficient workspace.

Laboratory window screens are specialized coverings designed to fit over windows in a laboratory setting. These screens are not your typical household window screens; they are crafted with specific materials and features to meet the unique demands of a laboratory environment. The primary purpose of these screens is to allow natural light and air to enter the laboratory while keeping out unwanted elements such as insects, dust, and other contaminants.

Window mesh screens play a crucial role in maintaining a clean and safe laboratory environment. Laboratories often require controlled levels of air quality and cleanliness to prevent contamination of experiments and samples. Mesh screens act as a physical barrier, allowing fresh air to circulate while preventing insects and debris from entering the space. This is particularly important in laboratories where biological experiments are conducted, as even the smallest contaminants can compromise the results.

Laboratories require different types of window screens based on their specific needs and the type of work conducted within them. Here are some common types of laboratory window screens:

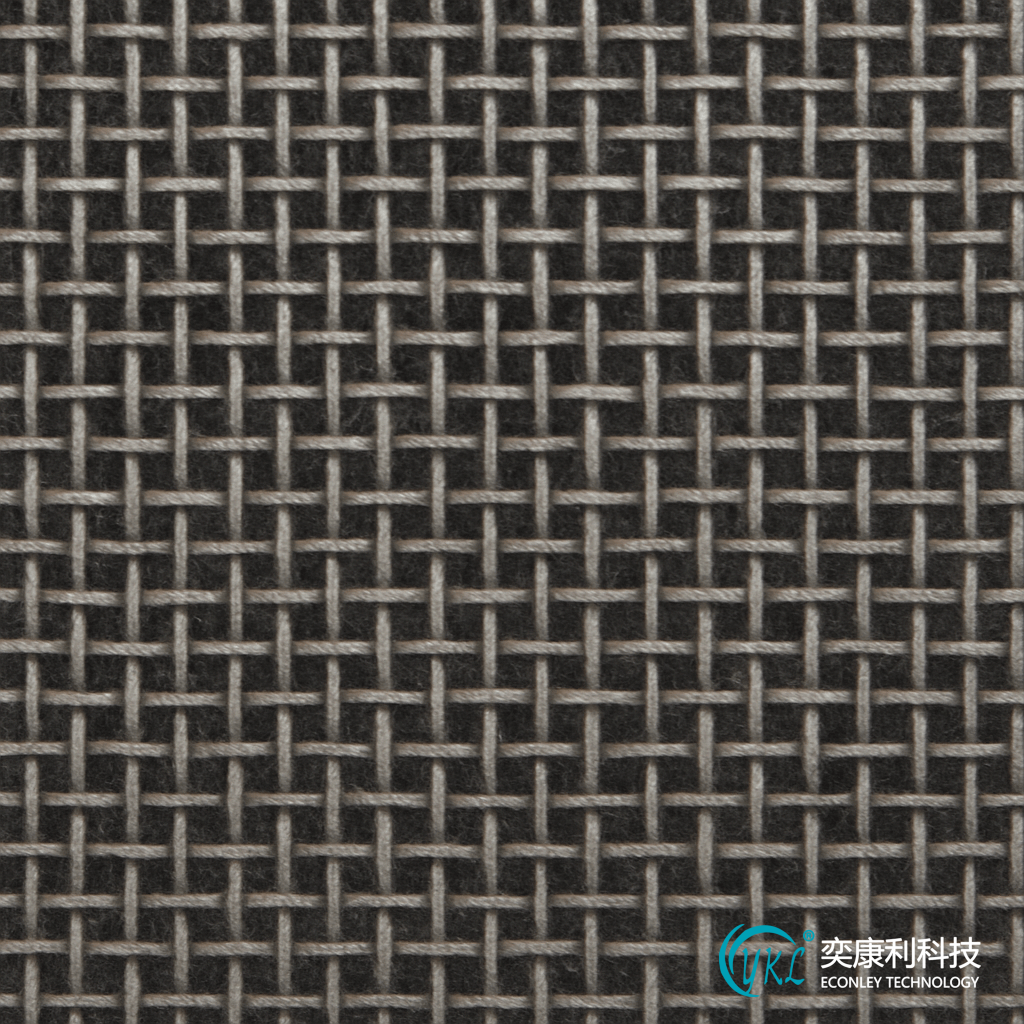

Stainless steel mesh screens are a popular choice for laboratories due to their durability and resistance to corrosion. These screens are capable of withstanding harsh chemical environments, making them ideal for labs where chemical experiments are frequently performed. The fine mesh of stainless steel screens effectively keeps out insects and debris while allowing for optimal air circulation.

Fiberglass mesh screens are another option for laboratory windows. They are lightweight, easy to install, and provide excellent visibility. Fiberglass screens are resistant to chemicals, making them suitable for most laboratory environments. Their flexibility allows them to fit various window sizes and shapes, ensuring a snug and secure fit.

Aluminum mesh screens are known for their strength and resistance to wear and tear. They are an excellent choice for laboratories that require a robust and long-lasting screen solution. Aluminum screens offer good visibility and airflow while preventing insects and contaminants from entering the lab.

Polypropylene screens are made from a type of plastic that is resistant to many chemicals, making them suitable for laboratories where chemical resistance is a priority. These screens are lightweight and easy to handle, providing a cost-effective solution for laboratories on a budget.

Laboratory window screens offer several advantages that contribute to a safe and efficient working environment. Here are some of the benefits:

By allowing fresh air to circulate while keeping out contaminants, window screens help maintain high air quality within the laboratory. This is essential for the health and safety of laboratory personnel and the integrity of experiments.

Natural light is crucial in a laboratory setting as it reduces the need for artificial lighting and creates a more pleasant working environment. Window screens allow natural light to enter the lab without compromising safety or cleanliness.

Insects and pests can be a significant concern in laboratories, especially those conducting biological research. Window screens act as a barrier, preventing pests from entering and potentially contaminating sensitive experiments.

Window screens are a cost-effective way to enhance the safety and functionality of a laboratory. They require minimal maintenance and can significantly reduce the need for additional air filtration systems.

When selecting window screens for a laboratory, several factors should be considered to ensure the best fit for the specific needs of the lab:

The material of the screen should be chosen based on the laboratory's environment. For labs dealing with harsh chemicals, stainless steel or polypropylene screens may be more suitable due to their resistance to corrosion and chemicals.

The mesh size of the screen determines its effectiveness in keeping out contaminants. Laboratories that require a higher level of cleanliness may opt for screens with a finer mesh to prevent even the smallest particles from entering.

Window screens should be easy to install and maintain. Screens that are lightweight and flexible, such as fiberglass or polypropylene, are often easier to handle and install.

Cost is always a consideration in any laboratory setting. While stainless steel and aluminum screens may offer superior durability, fiberglass and polypropylene screens provide a more budget-friendly option without compromising too much on quality.

Laboratory window screens are an often-overlooked component that plays a vital role in maintaining a controlled and safe laboratory environment. By choosing the right type of screen, laboratories can ensure the optimal balance of air quality, natural lighting, and cleanliness. Whether it's stainless steel, fiberglass, aluminum, or polypropylene, the right window screen can make a significant difference in the functionality and safety of a laboratory setting. Investing in quality window screens is a small step that can have a big impact on the success and efficiency of laboratory operations.